What is Dye Sublimation?

What is Dye Sublimation?

Dye sublimation printing is a unique process that allows full-colour images, text, and graphics to be transferred onto specially coated or polymer-based materials. Unlike traditional printing methods such as inkjet or screen printing, which apply liquid ink onto the surface of a material, dye sublimation uses specialised solid dyes (suspended in a liquid ink) that, when heated, transform directly into a gas—bypassing the liquid stage entirely. This gaseous dye will penetrate the polymer fibres of a receptive substrate, resulting in a permanent, high-resolution image that won’t crack, peel, or fade over time.

In contrast, other printing methods often sit on the surface and may be more prone to wear. We offer a variety of products that harness the power of this vibrant and durable printing technology – with all of our blanks being polymer coated and therefore sublimation ready. This range includes items such as ceramic & bone china mugs, photo slates, acrylic photo blocks, aluminium, woods and much more besides – today, there are few limits to what you can make with dye sublimation.

The process is quick and easy and as the equipment is quite compact, minimal working space is required. You can print as many or as few prints as you need therefore producing a ‘one off’, short run or multiples to suit your requirements. End results are vibrant, photo-realistic images on a wide range of unique personal and promotional products that your customers will love. Our five simple steps below will explain how Dye Sublimation works…

What We Offer:

We’ve been helping our customers find success with Dye Sublimation Printing for over 40 years, with comprehensive offerings of:

- Starter Kits available for those taking their first steps into personalisation.

- Dye Sublimation Printers, sublimation inks and heat transfer presses for those who simply wish to upgrade or expand their existing system.

- One of the widest ranges of sublimation blanks in the UK.

- A host of supporting accessories and consumable products.

- Full manufacturer backed warranties on all of our equipment.

Most importantly, we are proud to offer ongoing support to all of our customers – ensuring that they get the best possible advice before purchasing, help when setting up their equipment and answers to basic queries. In addition, we offer guidance on process procedures, including times, temperatures pressure settings – as well as free templates for all of our products – all combining to deliver the best results possible!

The 5 Steps to Dye Sublimation Printing

1. Create your artwork

Create your artwork on your PC or Mac using a standard design app. Packages such as Adobe Photoshop, CorelDraw or Illustrator are all fine to work with. Many customers also opt to use web based services such as Canva or similar. Use our product templates for fast accurate sizing and shaping. Photos or logos can be added via a range of methods – whether arriving digitally or being manually scanned or photographed.

Those who have purchased one of the Sawgrass printers have the added benefit of using Sawgrass’ online design suite MySawgrass & Sawgrass Print Utility. MySawgrass offers the ability to design artwork on any internet connected device (PC, Mac, tablet or phone) and access a library of hundreds of templates, with thousands of customisable designs – all at no extra cost!

- Pro Tip! When working with images, always choose the highest resolution available – or if unavailable, consider using an AI based image editor or up-scaling tool to enhance the artwork.

2. Printing your artwork

Print your artwork from your chosen Dye Sub printer. We supply sublimation inks for a range of printers, including Sawgrass’ Virtuoso line of printers – which range from A4 to A1 in size. For optimum results, it is important to select a printer and inks suitable for your needs and we are happy to discuss the available options.

The majority of our sublimation products have a printable face, therefore mirroring your artwork when printing is essential. This will ensure your artwork appears upright once you have transferred it onto a product. This rule however doesn’t apply to our glass and acrylic products as the receptive side of these products is the rear.

- Pro Tip! Paper selection can make a huge difference to the quality of the finished product. Select a tried, tested and trusted paper such as S-Race Vivid by Felix Schoeller for consistent results.

3. Prepare your product

The transfer is printed on to a specialist inkjet quality paper – we recommend S-Race for best results.

The print is then placed on the polymer coated blank, and secured in place with a small amount of heat resistant tape. We supply one of the widest ranges of products for sublimation printing in the UK, being authorised distributors of Sawgrass inks, Unisub woods, ChromaLuxe HD Photo Panels, Wasatch software and many other brand names.

- Pro Tip! Whilst many products will have a protective film that helps keep the product clean before use, some won’t – it’s always worth checking and cleaning the printable surface with a dry microfibre cloth before attaching the print (or some isopropyl alcohol if desired).

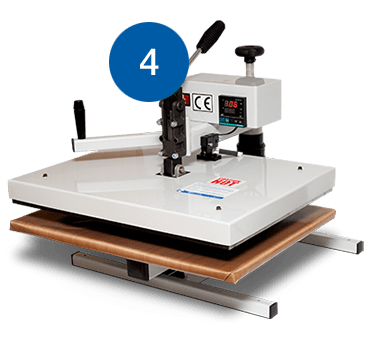

4.Transferring your artwork

Choose from our range of high quality Ultra-Deep Swing-head Presses to print onto flat products. The comprehensive range of flat sublimatable substrates includes plastic, metal, slates, glass, wall mount photo panels, jigsaws and much more.

The item is positioned in the appropriate Heat Transfer Press, heat and pressure are applied for the recommended short time. Our full wrap Mug Press can print from top to bottom of a standard Durham in approx 2½ minutes.

- Pro Tip! If you’re unsure of how best to assemble a job, what time or temperature to use or anythinge else, we offer help and advice by telephone, email or video call (Teams, Zoom or WhatsApp!).

5. The finished product

Remove the paper (taking care as the item is hot) and the process is complete. No mess, no fuss, no costly or time consuming set-ups. Sublimation is simple, fast and versatile. Produce a ‘one-off’ or larger quantities. Just print and press to create a variety of unique, personalised items.

- Pro Tip! When printing and pressing, some items (such as mugs) can benefit from being immersed in warm water to help them cool quicker. This helps to retain fine detail such as small text and sharp edges on photos – and also assists in keeping colours true to the original design.

How does Dye Sublimation compare to other print methods?

| Feature | Dye Sublimation | Inkjet Printing | Screen Printing | UV Printing |

| Ink Type | Solid dye (heat activated) | Liquid ink | Liquid ink | UV-Curable ink |

| Durability | Excellent – print becomes part of the material | Moderate – ink sits on the surface | Good – thick ink layers | Excellent – ink cured and hardened by UV light |

| Surface Penetration | Yes (for polymers) | No | No | No |

| Best For | Polyester fabrics, coated metals, ceramic mugs and mousemats | Paper / Card | Apparel, posters | Rigid uncoated surfaces like acrylic or wood |

Dye Sublimation – FAQs

What is Dye Sublimation?

This is often the first question we are asked. Broadly speaking, Dye Sublimation covers a number of phase transition processes – all of which involve dye particles shifting from a solid to a gaseous state without passing through a liquid phase.

There’s a few different technologies that rely on the process, such as dye sublimation photo printing (think instant print machines in your local supermarket) but the most popular variant today is dye sublimation transfer printing – or sublimation inkjet printing.

This particular process allows full colour images, text or graphics to be printed on to a carrier sheet, which can then be transferred to a polyester based textile – or a polymer coated object.

What Do I Need To Start Sublimating?

The core equipment for starting sublimation printing is simple – an inkjet printer capable of accepting dye sublimation inks (such as those supplied by Sawgrass Technologies), and some form of heat transfer press or sublimation oven. You’ll also need a PC or Mac to design or format your artwork and send it on to the printer.

We stock, supply and support a wide range of printers, heat presses and other accessories and we’re always happy to advise on a case-by case basis if you’re not sure exactly what you need to get started. Contact us telephone, email or direct message and we can help.

What about my PC specifications and what software will I need?

Most off the shelf PCs or Macs, should suffice and customers today will use a broad suite of apps – commonly, Adobe Photoshop, Canva and Affinity Designer, though most apps that have a ‘Print’ command will work just fine for Dye Sublimation Printing. If you have any specific queries or you aren’t sure, you contact us we can discuss what you may already have available to you and what may possibly be required in addition.

What kind of products can I produce?

There’s a huge variety of dye sublimation ready products out there – and we stock one of the widest ranges in the UK. Generally, sublimation ready means that these products will be white or light coloured and be produced from polyester or be coated with some form of polymer. All of our items are ready to print and press, with specific instructions and expert guidance on hand to make sure you get the right result first time.

Do I have to produce a lot of items to make Dye Sublimation worthwhile?

No. One of the advantages of sublimation printing is that you can cost effectively produce a one off, a short run or multiples to suit your customer’s needs. There’s no need to produce a large amount of items, you can comfortably make custom and bespoke designs on a pro-rata basis!

How Does Dye Sublimation Work?

Sublimation dyes will begin to move – or gas out – when given enough energy. As the dyes are exposed to heat, their rate of movement increases until the majority is released as gas.

Taking this a step further, if these gases encounter polymer fibres as they travel, they will penetrate those fibres, permanently staining or dyeing them.

In practical terms, Dye Sublimation printing requires three key conditions to work – temperature, time and pressure. Temperature sets the ink in motion, time allows the ink to fully move from one point to another, whilst pressure helps direct the flow of the gas from the transfer paper to the coated substrate. Achieving a good working balance of all three is critical to achieving a successful end product.

Do I Need A Lot Of Working Space?

No. The equipment is quite compact. It can usually be incorporated into an existing business space whilst others work from a small booths or retail outlets in shopping centres. Increasingly, home based businesses and side hustles are a thing – with many customers choosing to operate from spare rooms, outdoor workrooms and other spaces at home. A standard A4 based system can be operated within a couple of square metres – and these pieces of equipment are also relatively lightweight and portable, making them suitable to people who want to take their systems to craft fairs and other events.

I’ve never done any printing before. Is it difficult?

No – with only a little time and practice, you should find the process becomes familiar and easy. There are no messy or time consuming preparations and the Heat Transfer Presses are straightforward to use which means absolutely anyone can have a go at Dye-Sublimation Printing.

Are Profit Margins Good With Dye Sublimation?

Just like any business, there are a lot or considerations about whether it will be worthwhile and a suitable endeavour for you. However, dye sublimation is one of the more effective ways of producing one-off and short run products, thanks to the incredibly low barriers to entry. You’re also not reliant on external print services – you can do this all in-house. Over the course of a few short runs of products, a dye sublimation system has the potential to pay for itself quickly. So, when compared to other print methods, sublimation is extremely cost effective and can be very profitable.

Why not take a look at our ‘Start your own business’ guide on the website for pricing information and other tips on getting started.

Published by Nova Chrome UK – specialists in dye sublimation printing since 1983